Process Equipment & Service Company

Design

Engineering excellence

Let Our Experience Work For You

When it comes to design, PESCO is preeminent. With the capability to intricately design and specifically customize to meet your needs, PESCO knows how to maximize your production and give you seamless integration and a stress-free experience.

PESCO has an extensive and robust in-house engineering team dedicated to engineering excellence in every unit we manufacture. From start to finish, PESCO utilizes their experience to ensure flawless operations and exceptional products by working with you through:

- Initial concept

- Production management

- Fabrication

- Startup

- Training and ongoing engineering customer support

Why Choose PESCO For Your Process Equipment Design & Engineering?

PESCO’s Commitment to Quality

Excellence in Engineering Support & Continuous Improvement

Process Equipment Design FAQs

What types of process equipment does PESCO design?

PESCO designs and engineers a wide range of process equipment for oil and gas production, treating, and processing - including separators, heater treaters, dehydration units, and fully integrated modular systems.

Can PESCO design equipment from scratch or work with my existing plans?

Both. Our engineering team can create a completely custom design tailored to your sire conditions, or refine your existing design to improve performance, reduce costs, and simplify installations.

How involved can I be in the design process?

PESCO engineers collaborate directly with you at every stage - from concept and quoting to fabrications, startup, and training. You'll have ongoing communication and input throughout your project.

What engineering disciplines are represented on PESCO's design team?

Our in-house team includes Chemical, Civil, Electrical, Mechanical and industrial Engineers - with more than 200 years of combined experience in process equipment design and manufacturing.

How does PESCO ensure equipment integrates smoothly into existing systems ?

We take a fully integrated approach to every project. Our designs are carefully sized and configured to ensure seamless connection with your existing production equipment, maximizing output while minimizing energy use and emissions.

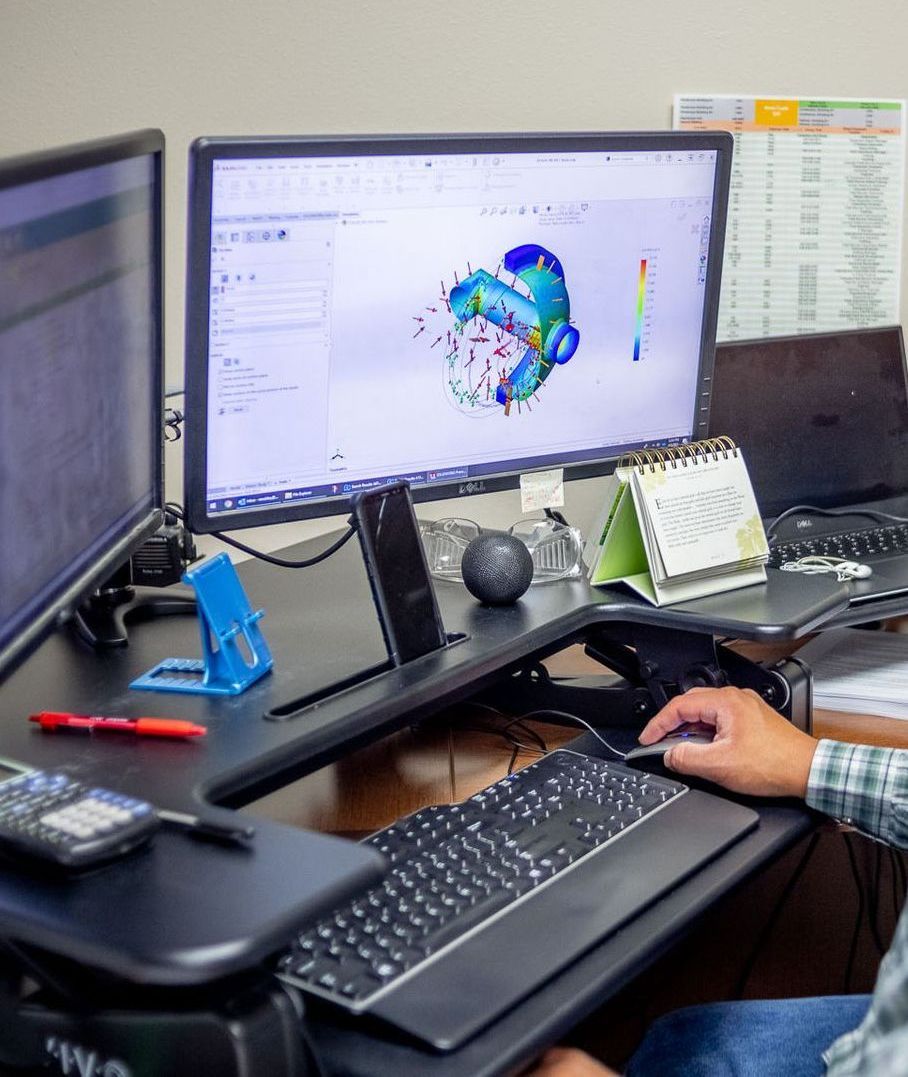

What software and tools does PESCO use for design and drafting?

PESCO employs advanced 3D CAD modeling and process simulation software, enabling precise visualization, efficient fabrication, and accurate performance forecasting.

What kind of post-installation support does PESCO provide?

Our commitment doesn't end after delivery. We offer startup assistance, on-site training, and ongoing engineering support to ensure long-term reliability and continous improvement.

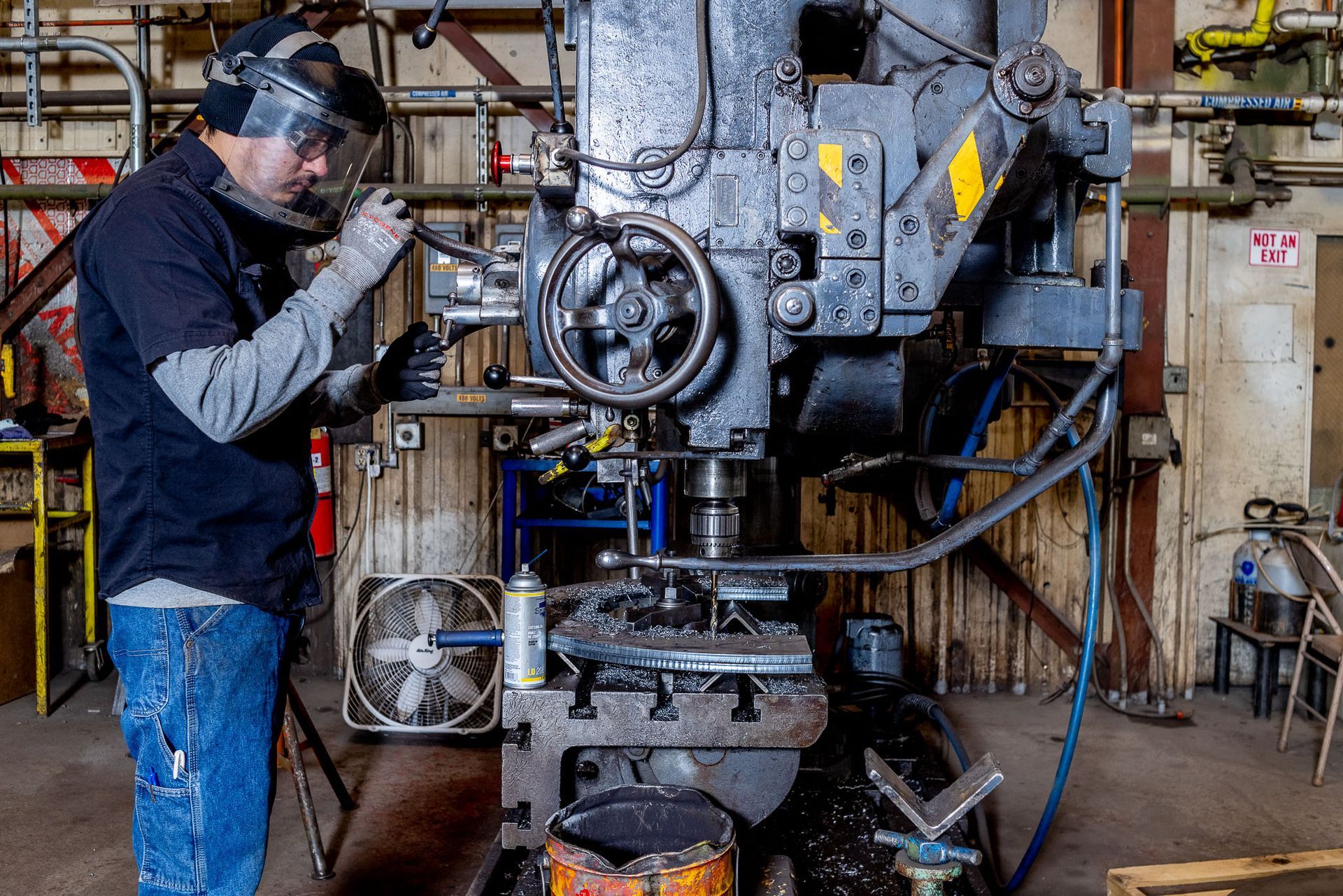

Can PESCO refurbish or upgrade existing production equipment?

Yes. We are R Stamp Certified and offer complete upgrade, repiar, and modification services to extend the life of your equipment and enhance performance.

How does PESCO maintain quality throughout the design and build process?

Our engineering and quality control departments include senior craftsman, an EE98 Master Electrician, and a dedicated team of draftsmen who uphold our standards of excellence at every step - from design to delivery.

How can I get started with a PESCO design project?

Reach out through our contact page or call us directly to discuss your production goals. Our engineers will review your requirements and provide a tailored proposal, timeline, and cost estimate.

Upgrade & Refurbish

Bring new life to your production equipment with our R Stamp Certified repair or performance-enhancing modifications.